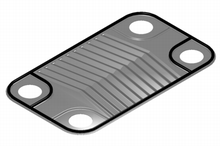

The plate heat exchanger consists of a specific number of plates

arranged between the pressure & the fixed frame. The plates are

having corrugations with different designs which increase the total

surface area for the heat exchange.

The plates

are movable within the frame and rest on the carrying bar on the top and

the bottom of the frame. The plates are arranged in pairs which are

opposite of each other forming a honey comb pattern when viewed

sideways.

The plate corrugations promote fluid

turbulence and increase the heat transfer. The fixed and the pressure

plate are supported by the supporting column. The plates are fitted with

each other with gaskets which seal the material from coming out

sideways as well as through the holes on the plates. The alternate

arrangement of the gaskets prevents the mixing of the fluids within the

channels.

Design of plate and frame heat exchangers

The plate heat exchanger (PHE) is a specialized design well suited to transferring heat between medium- and low-pressure fluids. Welded, semi-welded and brazed heat exchangers are used for heat exchange between high-pressure fluids or where a more compact product is required. In place of a pipe passing through a chamber, there are instead two alternating chambers, usually thin in depth, separated at their largest surface by a corrugated metal plate. The plates used in a plate and frame heat exchanger are obtained by one piece pressing of metal plates. Stainless steel is a commonly used metal for the plates because of its ability to withstand high temperatures, its strength, and its corrosion resistance. The plates are often spaced by rubber sealing gaskets which are cemented into a section around the edge of the plates. The plates are pressed to form troughs at right angles to the direction of flow of the liquid which runs through the channels in the heat exchanger. These troughs are arranged so that they interlink with the other plates which forms the channel with gaps of 1.3–1.5 mm between the plates.

The plates produce an extremely large surface area, which allows for the fastest possible transfer. Making each chamber thin ensures that the majority of the volume of the liquid contacts the plate, again aiding exchange. The troughs also create and maintain a turbulent flow in the liquid to maximize heat transfer in the exchanger. A high degree of turbulence can be obtained at low flow rates and high heat transfer coefficient can then be achieved.

A plate heat exchanger consists of a series of thin, corrugated plates which are mentioned above. These plates are gasketed, welded or brazed together depending on the application of the heat exchanger. The plates are compressed together in a rigid frame to form an arrangement of parallel flow channels with alternating hot and cold fluids.

As compared to shell and tube heat exchangers, the temperature approach in a plate heat exchangers may be as low as 1 °C whereas shell and tube heat exchangers require an approach of 5 °C or more. For the same amount of heat exchanged, the size of the plate heat exchanger is smaller, because of the large heat transfer area afforded by the plates (the large area through which heat can travel). Increase and reduction of the heat transfer area is simple in a plate heat-exchanger, through the addition or removal of plates from the stack.

Evaluating plate heat exchangers

All plate heat exchangers look similar on the outside. The difference lies on the inside, in the details of the plate design and the sealing technologies used. Hence, when evaluating a plate heat exchanger, it is very important not only to explore the details of the product being supplied, but also to analyze the level of research and development carried out by the manufacturer and the post-commissioning service and spare parts availability.

An important aspect to take into account when evaluating a heat exchanger are the forms of corrugation within the heat exchanger. There are two types: intermating and chevron corrugations. In general, greater heat transfer enhancement is produced from chevrons for a given increase in pressure drop and are more commonly used than intermating corrugations.

Flow distribution and heat transfer equatio

Design calculations of a plate heat exchanger include flow distribution and pressure drop and heat transfer. The former is an issue of Flow distribution in manifolds. A layout configuration of plate heat exchanger can be usually simplified into a manifold system with two manifold headers for dividing and combining fluids, which can be categorized into U-type and Z-type arrangement according to flow direction in the headers, as shown in manifold arrangement.Bassiouny and Martin developed previous theory of design. In the recent years Wang unified all the main existing models and developed a most completed theory and design tool.

The total rate of heat transfer between the hot and cold fluids passing through a plate heat exchanger may be expressed as: Q = UA∆Tm where U is the Overall heat transfer coefficient, A is the total plate area, and ∆Tm is the Log mean temperature difference. U is dependent upon the heat transfer coefficients in the hot and cold streams.

No comments:

Post a Comment